industrial Reverse Osmosis Systems

Purified water is an essential part of the food, beverage, cosmetic, chemical, and pharmaceuticals industries as well as power plants and refineries.

Purified water can be obtained through reverse osmosis systems. A complete reverse osmosis system includes several steps to get the result ofeffective purified water.

We are the leading supplier of industrial reverse osmosis systems. With our qualified professionals, we are able to offer customized systems in a variety of ranges according to your requirements and needs

Benefits of RO Purified Water:

• RO water will reduce maintenance costs by decreasing scaling in boiler tubing, lowering the operating cost of boilers by allowing better heat transfer

• Utilization of purified RO water rather than non-purified source water drastically minimizes scale and sludge damage to heat exchangers and spray nozzles, reducing equipment failure and maintenance costs

• Effective implementation can provide huge savings by reducing usage of water, chemicals, energy and can help companies meet the requirements for ISO 9000 and ISO 14000, HACCP standards

• Environmentally friendly - Utilization of purified RO water for evaporative make-up of chemical baths drastically reduces the frequency of bath dumping; thereby minimizing water source usage, wastewater generation, and chemical consumption

• Better tasting food and beverages

• Trusted zero contamination system

Pro Line Ultra Series

Ultra-Series Reverse Osmosis Systems, are state-of-the-art, versatile systems for treating municipal and well water supplies. Ultra-Systems range in size from 2,600 to 5,200 gallons per day. The Ultra-Series RO systems have minimal energy consumption, low maintenance and excellent operating costs.

Big on standard features, yet compact, the Ultra-Series features a robust design that allows for versatility in the event of feed water quality and temperature variations. All systems come standard with Ultra Low Energy Membranes, and offer high rejection and flow rates for quality system performance. These Ultra Low Energy Unit, feature ½ HP or ¾ HP multi-stage booster pumps with stainless steel bodies, for Ultra performance and corrosion resistance.

All models are equipped with the iControls™ RO System Controller, for precise control of auto-flush options, operation indication, pre-treatment and storage tank status, & much more!

Basic Model Features : |

Deluxe Model Upgraded Features : |

||||||||||

• Franklin BT4 Series Multi-Stage Pumps |

• Auto-Flush Solenoid Valve & Multiple Programming |

||||||||||

|

|||||||||||

|

|

||||||||||

* Product flow and recovery rates are based on feed-water condition of 1,000 ppm of TDS @ 77ºF / 25ºC. Treatment ability of the RO System is dependent on feed water quality. Higher TDS and/or lower temperatures will reduce product flow. Performance projections should be run for each installation. |

|||||||||||

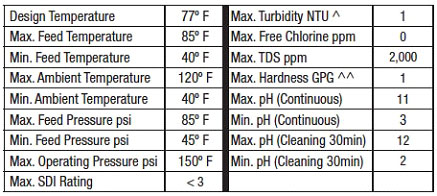

CONDITIONS FOR OPERATION: |

|||||||||||

|

|||||||||||

Pro Line Ultra Series

Ultra-Series Deluxe Commercial Reverse Osmosis Systems are state-of-the-art, versatile systems for treating municipal and well water supplies. This line-up features systems with nominally rated outputs of 7,800, 10,400, and 15,600 gallons per day on 77F/25C water temperature. All Ultra High-Output systems have low energy consumption, maintenance, and operating costs.

Big on standard features, yet compact, these Ultra-Series Deluxe systems feature a robust design that allows for versatility in the event, of feed water quality and temperature variations. All systems come standard with Ultra Low Energy Membranes, that offer high rejection and flow rates for quality system performance. All Ultra-Series Deluxe systems, feature Webtrol multi-stage booster pumps. These Ultra-Series Deluxe units are all standard with Codeline fiberglass Membrane housings.

All models are equipped with the model iControls™ ROC-5 RO System Controller, for precise control of auto-flush options, Conductivity monitoring, operation indication, powered relay output, pre-treatment and storage tank status, and much more!

Basic Model Features : |

|

• Powder-Coated Aluminum Frame |

• Permeate Flow Meter |

|

|

* Product flow and recovery rates are based on feed-water condition of 1,000 ppm of TDS @ 77ᵒF / 25ᵒC. Treatment ability of the RO System is dependent on feed water quality. Higher TDS and/or lower temperatures will reduce product flow. Performance projections should be run for each installation. |

|

CONDITIONS FOR OPERATION: |

|

|

|